Fire-rated glass for doors falls into one of these two categories and understanding the difference will help you select the right glazing for your application.

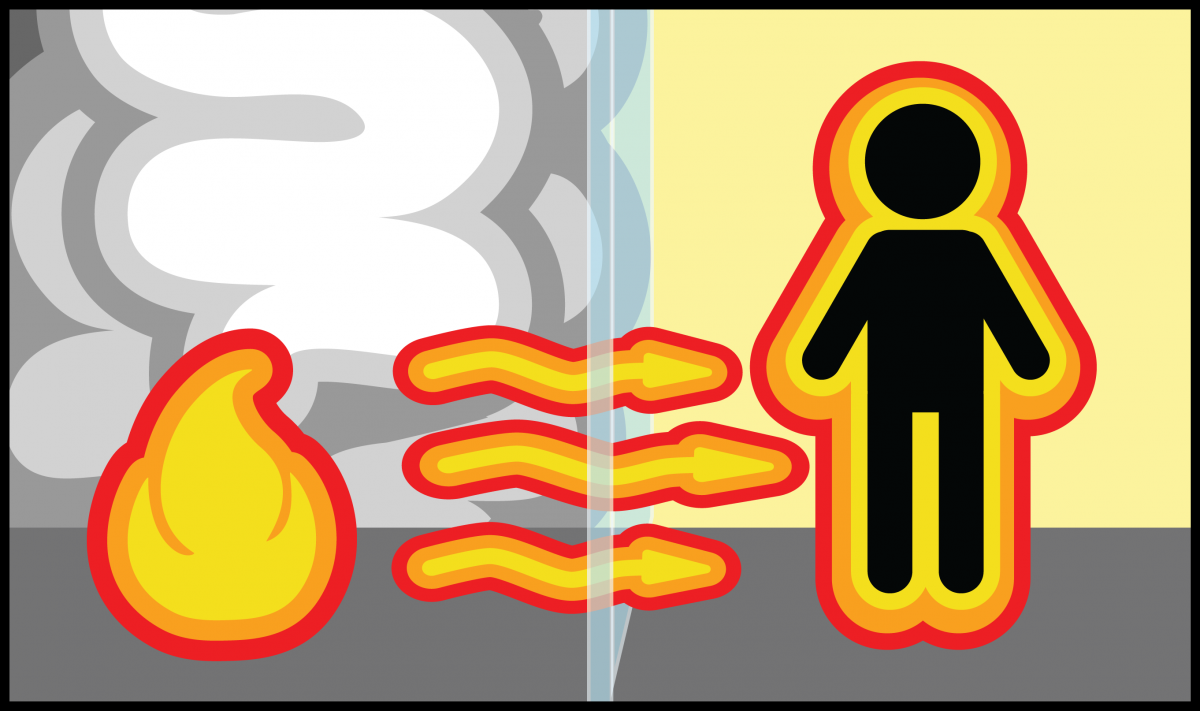

Fire Protective Glass

Compartmentalizes Smoke and Flames.

Fire Protective Glass does not prevent radiant heat transfer to the other side of the glass, and can be fire-rated up to 180 minutes with size limitations under the IBC.

Glass-ceramics and specialty tempered glass are considered fire-protective glass and are the most commonly-used in fire-rated doors when the building code calls for an opening protective.

Many fire-rated doors require Fire Protective Glazing. Allowed sizes are dictated by IBC and limited in the maximum size tested. Fire protective glass size in 60 and 90 minute doors in exit enclosures and exit passageways is limited to 100 square inches whether or not the building is sprinklered, to protect occupants from heat while exiting.

Look for Glazing Tested to These Standards:

NFPA 252 or UL 10B or UL 10C | NFPA 257 or UL9

Canada: CAN/ULC-S104 | CAN/ULC-S106

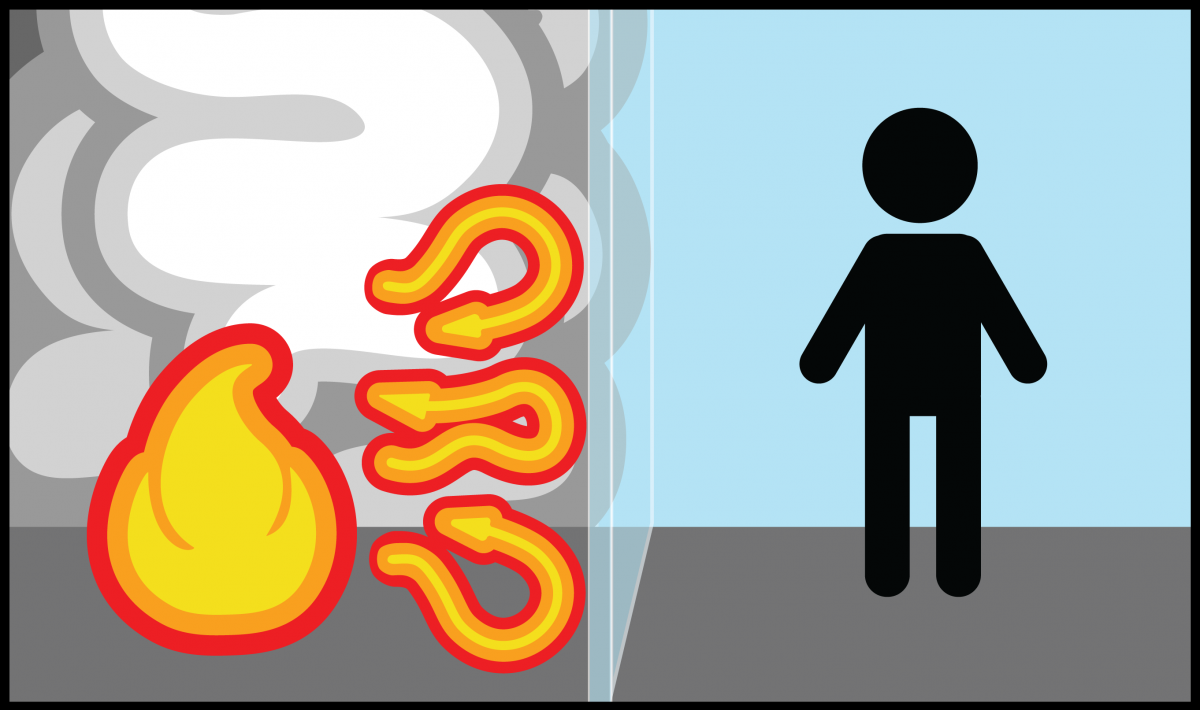

Fire Resistive Glass

Contains Flame and Smoke and Blocks Radiant Heat.

Fire resistive glass prevents the transmission of radiant heat through glass that can ignite paper, drapes, clothing and other combustible materials within 20 feet. This type of glazing can be fire-rated up to 90 minutes, but is regulated as a fire-resistive wall assembly.

Glazing temperature is limited to a rise of 250° F on the non-fire side during a specified time period. This glass is typically a multi-layer laminate of fire-resistive layers, which when exposed to heat, expands, providing an insulated layer of protection that holds broken glass in place and prevents the spread of fire, smoke, and thermal heat radiation.

Fire Resistive glazing can generally be used in larger sizes than Fire Protective because it resists heat transfer. Examples include wall applications requiring a 60-minute or greater fire rating that must meet temperature-rise criteria, such as stairwells, exit access corridors, or other fire barriers dividing interior construction.

Look for Glazing Tested to These Standards:

ASTM E119 or UL 263 | NFPA 252 or UL 10B or UL 10C | NFPA 257 or UL9

Canada: CAN/ULC-S101 | CAN/ULC-S104 | CAN/ULC-S106

What determines which glass to use in my application?

The International Building Code (IBC) provides the overarching guidance for specifying, test standards and installation under Section 716 -“Opening Protectives”. In that section, each type of opening is identified along with the exact testing standard that the glass needs to be tested to. In addition, the IBC requires that fire-protective and fire-resistive glazing assemblies have a permanent label that indicates what criteria the glass meets and the minute rating. Your local code official can provide valuable assistance in selecting glazing and vision frames for a fire-rated door to meet current codes for your area.

What do the permanent markings on fire-rated glazing mean?

| MARKING | DEFINITION OF MARKING | FIRE TEST STANDARD |

|---|---|---|

| W | Meets wall assembly criteria | ASTM E119 or UL263 |

| FC | Meets floor/ceiling criteria | ASTM E119 or UL263 |

| OH | Meets fire window assembly criteria including the hose stream test | NFPA 257 or UL9 |

| D H T | Meets fire door assembly criteria Meets fire door assembly hose stream test Meets 450° F temperature rise criteria for 30 minutes | NFPA 252 or UL 10B or UL10C |

| XXX | The time in minutes of the fire resistance or fire protection rating of the glazing assembly. | – |

What do those testing standards mean?

The tests below must be conducted by a nationally recognized testing laboratory (NRTL). When the glass product or system passes, it is given a listing and label from the test lab showing what it has been tested to.

NFPA 80: Standard for Fire Doors and Other Opening Protectives, regulates the installation and maintenance of assemblies and devices used to protect openings in walls, floors, and ceilings against the spread of fire and smoke within, into, or out of buildings.

NFPA 252: Standard Methods of Fire Tests of Door Assemblies evaluates the ability of a door assembly to remain in a wall opening during a prescribed fire test exposure including hose stream testing, for a specific duration.

UL10B: Standard for Safety Fire Tests of Door Assemblies. These methods of fire tests are applicable to door assemblies to retard the passage of fire, and to evaluate the ability of a door assembly to remain in an opening during a predetermined test exposure, including hose stream testing.

UL10C: Standard for Positive Pressure Fire Tests of Door Assemblies. These methods of fire tests are applicable to door assemblies to retard the passage of fire, and to evaluate the ability of a door assembly to remain in an opening during a predetermined test exposure, including hose stream testing.

UL263: Standard for Fire Tests of Building Construction and Materials. Evaluates the length of time that the assemblies will contain a fire or retain their structural integrity, or both during a predetermined test exposure that includes the hose stream test. Heat transmission through the door is measured.

ASTM E119: Standard Test Methods for Fire Tests of Building Construction and Materials for Fire Resistive Openings. Evaluates the duration for building elements to contain a fire while retaining their structural integrity during a predetermined test exposure. Measures the transmission of hot gases and heat through the door, and includes hose stream testing.

CAN ULC-S101: Standard Methods of Fire Endurance Tests of Building Construction and Materials. Hourly ratings are applicable to floors, roofs, beams, columns and walls in accordance to the National Building Code of Canada.

CAN ULC-S104: Standard Method for Fire Test of Door Assemblies. Fire test method for window assemblies for use as closures in openings in walls and partitions that are fire separations in accordance to the National Building Code of Canada.

Withdrawn Standards

Some products may have been tested to these standards in the past, so you may see these listed in product specifications.

ASTM E2074: Hose Stream Test. Now included in Other Testing Standards

ASTM E2010: Standard Test Method for Positive Pressure Fire Tests of Window Assemblies SEE UL10C

NFPA 251: Test of Nonbearing Walls and Partitions – Fire Tests – Hose stream. REPLACED BY ASTM E119 & UL 263

Who Performs the Testing?

Nationally recognized testing laboratories (NRTL) such as Underwriters Laboratories (UL) or Intertek Warnock-Hersey perform these tests in specially-designed facilities that are equipped with monitoring equipment to evaluate the performance of the glass as part of a fire assembly.

How is Glazing Tested to Achieve a Fire-Rating?

Fire Protective Glass:

Glass is tested in a Fire Endurance Test to ensure that it can remain intact and block flames and smoke for a specified period of intense heat. Glass is installed in a door assembly in the wall, and then heated on one side by a furnace for a designated time. To pass this test, the glass must retain its integrity, showing no signs of breakage or escaped flames. NFPA 80 3.3.57 defines Fire Protection Rating as “…the designation indicating the duration of the fire test exposure to which a fire door assembly or fire window assembly was exposed and for which it successfully met all acceptance criteria as determined in accordance with NFPA 252; ANSI/UL10B or ANSI/UL10C; or NFPA 257 or ANSI/UL9”.

Fire Resistive Glass:

Must be tested for Fire Endurance Test as part of a wall assembly under ASTM E119 or UL 263. Not only does the glass have to resist flame and smoke, but the temperature on the unexposed surface of the glass may not exceed 250°F above ambient. The assembly tested must not allow the passage of flame or gases hot enough to ignite combustible material for a period equal to that for which classification is desired, and must pass the hose stream test. NFPA 80 3.3.60 defines Fire Resistance Rating as “…the time in minutes or hours that materials or assemblies have withstood a fire exposure as established in accordance with the test procedures of ASTM E119 or ANSI/UL 263”.

What is a Hose Stream Test?

The hose stream test is generally performed immediately after the heat test above. The hot glass is sprayed with water from a fire hose at specified pressures. The cooling, impact and erosion created by the hose stream tests the integrity of the glass and frames and eliminates inadequate materials. The wall or partition must have sustained the applied load during the hose stream test without allowing an opening that permits a projection of water from the stream beyond the unexposed surface during the time of the test.

This information is provided for reference only, as Activar Construction Products Group, Inc. does not provide recommendations for a specific application. Please consult the actual code publications and the Authority Having Jurisdiction (AHJ) regarding building code compliance.