Updated 12/13/2023

OSHA Updates for Fall Protection:

In 2017, OSHA updated and renumbered the fall protection standards section 1910.23 for walking working surfaces to make them more consistent with Section 1926.502 fall protection for construction. Several of the section numbers changed—for your reference, the previous section numbers are indicated in brackets such as [1910.23(a)(4)]. The two new sections addressing fall protection for walking working surfaces are 1910.28 and 1910.29. Below are the specific OSHA standards and corresponding IBC codes for roof hatch safety railings.

About IBC and OSHA

International Building Code (IBC) establishes minimum requirements for building systems. States and cities adopt IBC codes at different rates, and may not be utilizing the 2024 version at this time.

The Occupational Safety and Health Administration (OSHA) helps to assure safe and healthful working conditions by setting and enforcing standards. Inspectors enforce the current national standard, except in cases where a state has a more stringent OSHA code.

Standards For Fall Protection Requirements On Rooftop Openings

OSHA 1910.28(b)(1)(i) [1910.23(a)(4)]

Except as provided elsewhere in this section, the employer must ensure that each employee on a walking-working surface with an unprotected side or edge that is 4 feet (1.2 m) or more above a lower level is protected from falling by one or more of the following: Guardrail systems; safety net systems; or personal fall protection systems, such as personal fall arrest, travel restraint, or positioning systems.

IBC1015.7 Roof Access:

Guard shall be provided where the roof hatch opening is located within 10 feet (3.05m) of a roof edge or open side of a walking surface and such edge or open side is located more than 30 inches (76.2cm) above the floor, roof or grade below. Exception: Guards are not required where personal fall arrest anchorage connector devices that comply with ANSI/ASSE Z359.1 are installed.

Note: OSHA is providing more flexibility to the employer to protect workers from falls by choosing from a range of accepted fall protection systems.

Standards for Height and Midrail of Guards

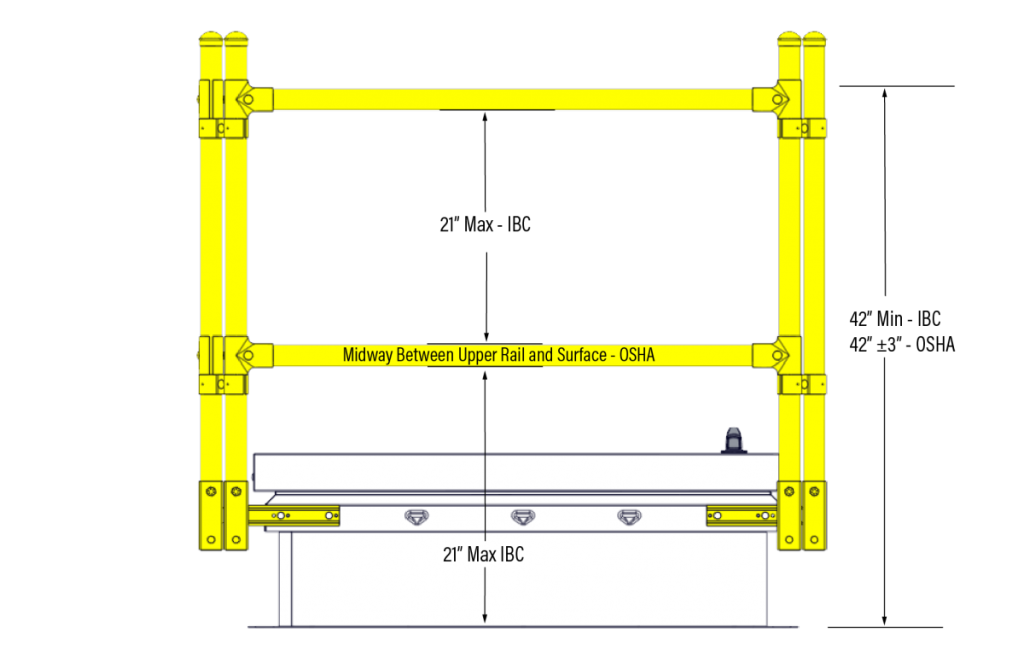

OSHA 1910.29(b)(1) [1910.23(e)3(v)(a)]

The top edge height of top rails, or equivalent guardrail system members, are 42 inches(1.07 m), plus or minus 3 inches (8 cm), above the walking/working surface. The top edge height may exceed 45 inches (1.14 m), provided the guardrail system meets all other criteria of paragraph (b) of this section.

IBC 1015.3 Guard Height:

Required guards shall be not less than 42 inches (1.07m) high, measured vertically as follows: From the adjacent walking surfaces.

Note: Since IBC requires at least a 42” high guard rail , a railing which is 42-45” high will comply with both.

OSHA 1910.29(b)(2)(i) [1910.23 (3)(e)]

Midrails are installed at a height midway between the top edge of the guardrail system and the walking working surface.

IBC1015.7 Roof Access:

The guard shall be constructed as to prevent the passage of a

sphere 21 inches (53.3cm) in diameter.

Note: IBC standards require all openings in the railing to be 21” or less. Railing systems with adjustable height midrails provide more flexibility to meet both of these standards.

Standards for Load-Bearing of Railing

OSHA 1910.29(b)(3)[1910.23(e)(3)(iv)]

Guardrail systems are capable of withstanding, without failure, a force of at least 200 pounds (890 N) applied in a downward or outward direction within 2 inches (5 cm) of the top edge, at any point along the top rail.

OSHA 1910.29(b)(4)[1910.23(e)(3)(v)(b)]

When the 200-pound (890-N) test load is applied in a downward direction, the top rail of the guardrail system must not deflect to a height of less than 39 inches (99 cm) above the walking-working surface.

OSHA 1910.29(b)(5)

Midrails, screens, mesh, intermediate vertical members, solid

panels, and other equivalent intermediate members are capable of withstanding, without failure, a force of at least 150 pounds (667 N) applied in any downward or outward direction at any point along the intermediate member.

IBC 1607.9.1

1607.9.1 Concentrated load handrails and guards shall be designed to resist a concentrated load of 200 pounds (0.29 kN) in accordance with section 4.5.1. of ASCE 7.

1607.9.11 Uniform load handrails and guards shall be designed to resist a linear load of 50 pounds per linear foot (0.73 kN/m) in accordance with Section 4.5.1 of ASCE 7. Exceptions for Group I-3, F, H and S occupancies for areas that are not accessible to the general public and have an occupant load less than 50, the minimum load shall be 20 pounds per for (0.29 kN/m).

1607.9.1.2 Guard component loads balusters, panel fillers and guard infill components, including all rails except the handrail and the top rail, shall be designed to resist a concentrated load of

50 pounds (0.22 kN).

Note: OSHA and IBC standards are the same for the top rail, however OSHA standards for the intermediate rail is 150 lbs, while IBC is only 50 lbs.

Standards for Railing Construction

OSHA 1910.29(b)(6) [1910.23(e)(3)(v)]

Guardrail systems are smooth-surfaced to protect employees from injury, such as punctures or lacerations, and to prevent catching or snagging of clothing.

OSHA 1910.29(b)(7) [1910.23(3)(e)]

The ends of top rails and midrails do not overhang the terminal posts, except where the overhang does not pose a projection hazard for employees.

OSHA 1910.29(b)(9)[1910.23(e)(3)(ii)]

Top rails and midrails are at least 0.25-inches (0.6 cm) in diameter or in thickness.

IBC

IBC does not currently specify diameter sizing for guards.

Note: The prior OSHA standard required a nominal size of 1-1/2” diameter for guards, so this is a significant change.

Standards for Gates

OSHA 1910.29(b)(13) [1910.23(a)(2)]

When guardrail systems are used around holes that serve as points of access (such as ladderways), the guardrail system

opening: have a self-closing gate (13)(i) that slides or swings away from the hole, and is equipped with a top rail and midrail or equivalent intermediate member that meets the requirements in paragraph (b) of this section; or is offset to prevent an employee from walking or falling into the hole (13)(ii).

Note: This section helps clarify the requirement of self-closing gates over chains to protect the opening. Chains are a common option out in industry that will require a retrofit self closing gate to comply with OSHA where applicable.

For information on the ACPG Series of roof hatches and railings or to view submittals, see our roof accessories section.

This document is a guideline only, as interpretation of building codes may vary. Consult your local AHJ for appropriate standards in your area.