About Hurricane Zone Ratings for Doors:

Buildings in hurricane zones are designed to withstand wind speeds based on a specific geographic location and probabilities of occurrence. Wind zone maps from the National Weather Service and documents from the American Society of Civil Engineers, have been used to formulate building codes that can withstand these type of weather events. In Florida, for example, different wind zone maps are used depending on the risk category of structures.

Buildings do not just have to resist a steady wind, but must also hold up to the fluctuation of pressures both positive and negative called cyclic pressure. Cyclic pressure can occur both before and after impact by windborne debris and all of the building components, including the door assembly must be able to endure both sustained winds and gusts in a windstorm.

Although hurricanes are not a sudden event like a tornado, the building envelope needs to protect the building’s contents from the damaging effects of continued wind and rain. Internal pressurization has the potential to cause even more damage when the wall of a building is breached by wind, causing the internal pressure in the building to increase, resulting in outward acting pressure on the other walls and the roof.

All components of doors rated to withstand hurricanes must pass one or more tests and be properly labelled with information on the certification. The fully-assembled unit – door, vision frame with glazing or louver must be tested as a whole, not just the components. These test methods are applicable to the design of the entire door assembly, their installation and ability to remain unbreached during a windstorm.

How are Door Components Tested?

An approved, independent testing agency performs these tests which include a missile propulsion device, an air pressure system, and a test chamber to model some conditions which may be representative of windborne debris and pressures in a windstorm environment.

Door components must pass impact-resistance testing in which the door is subjected to both large and small missiles. Test results are shown as an impact rating, missile level and pounds per square foot rating.

In addition, air leakage and water penetration are measured under static and/or differential pressure conditions.

Vison lites and door louvers must pass the tests without penetration by the missile and remain in their frames without a tear or crack that exceeds the test specification requirements.

What is Florida Product Approval?

Because buildings in the state of Florida are subjected to extreme weather in the form of hurricanes, they have developed stringent codes for building types in each of their high wind zones. To obtain approval to be used in buildings in these zones, products used in construction must go through an approval process that may include product testing or other method of verifying suitability for the application intended. See page 3 for more information on testing standards for door components.

To search the Florida Product Approval database, use this link.

What is Miami-Dade County, Florida Approval?

Miami-Dade County is located in the highest wind zone area in Florida, and has developed standards to protect buildings from those hazards. Manufacturers must submit construction products for certification and/or testing separately from a Florida Building Code approval. Generally, the standards are more restrictive than the Florida Product Approval requirements. See page 3 for more information on testing standards for door components.

To search the Miami-Dade database use this link.

More About Testing Standards:

ASTM E1886 & FBC TAS 203:

Standard test method for impact-resistant performance of exterior windows, curtain walls, doors and impact protective systems based on positive and negative design pressure(s). During this test, a door is first subjected to specified missile impact(s) followed by the application of a specified number of cycles of positive and negative static pressure. The assembly must satisfy the pass/fail criteria established by the specifying authority, which may allow damage such as deformation, deflection, or glass breakage.

ASTM E1996 & FBC TAS 201:

This specification covers exterior windows, glazed curtain walls, doors and impact protective systems used in buildings located in geographic regions that are exposed to hurricanes or windborne debris. The testing included both a large missile test, and small missile test. Test results are shown with an impact rating such as “350 ft lb”, a missile level such as “D” and a pounds per square foot rating for cyclic wind pressure loading such as “55 psf”.

ASTM E330:

This test method is a standard procedure for determining structural performance under uniform static air pressure difference using a test chamber. This typically is intended to represent the effects of a wind load on exterior building surface elements.

ASTM E283:

This test determines the air leakage rates of exterior windows, curtain walls, and doors under specified differential pressure conditions and constant temperature and humidity.

ASTM E331:

This test method covers the resistance of exterior windows, curtain walls, skylights, and doors to water penetration when water is applied to the outdoor face and exposed edges simultaneously with a uniform static air pressure at the outdoor face higher than the pressure at the indoor face.

ASTM E1300:

Determines the load resistance (LR) of specified glass types, including combinations of glass types used in a sealed insulating glass (IG) unit, exposed to a uniform lateral load of short or long duration, for a specified probability of breakage

FBC TAS 202:

Florida Building Code – Uniform structural load standards and cycle testing of impact-resistant building envelope components using uniform static air pressure.

NFPA 252, UL10C:

National Fire Protection Association codes. This standard outlines the methods of fire testing doors assemblies and their suitability when fire resistance of a specific duration is required. UL10C is the standard for positive pressure fire tests of door assemblies.

Labeling:

Commercially produced products that pass one or more of these standards should have a certificate or label that identifies which standard(s) it has passed. These are usually listed by the test standard number such as TAS-201 , ASTM E 1886, etc. Note that Florida Building Code and Miami-Dade County test standards may not be the same. Consult the code official before ordering.

Air Louvers Products

Air Louvers has door component products with the approvals needed in Florida, and have been tested to withstand both impact and cyclical testing. Our fire and hurricane-rated vision lite can meet both fire and hurricane codes in your area. All vision frames include listed and approved glazing that meet the same stringent code requirements, saving you time and research to find the right approved glazing. Vision frames and louvers are labelled for easy identification by code officials.

Quick Install: VLFEZHRC

Includes vision frame, glazing and sealant.

- ASTM E330, E1886, E1996

- ANSI 250.13

- TAS 201, TAS 202, TAS 203

- Design pressure +/- 55 psf,

- Impact resistance 350 ft-lbs, Missile D, Wind zone 4

Thru-bolt: VLFIGHRC

Includes vision frame, glazing, sealant, glazing tape and O-rings.

- ASTM E330, E1886, E1996

- ANSI 250.13

- Design pressure +/-70 psf

- Impact resistance 350 ft-lbs, Missile D, Wind zone 4

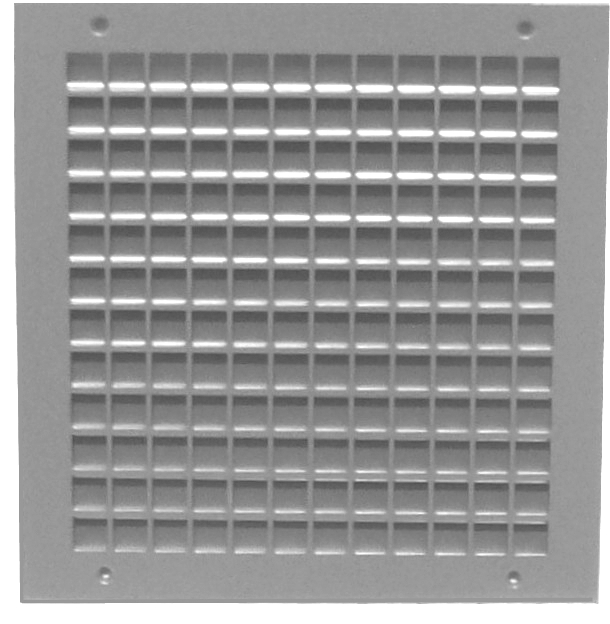

Door Louver: 1500AHR

- ASTM E330, ASTM E1996

- ANSI A250.13

- TAS 203, 201, 202

- ASTM E 1886

- Design pressure 60 psf

- Impact resistance 350 ft-lbs.