FIRE-RATED

Fire-rated floor doors are designed to prevent the transmission of heat and flame through the floor/ceiling fire barrier and are required for openings in fire-rated floors. By code, doors must be tested and approved to meet certain fire-resistive criteria based on the rating of the floor. They are not required for all floor types, so check with your local code authority (AHJ) before selecting your floor door. Fire doors are not intended for wet or exterior installation.

These doors are tested to standards that determine the ability of the fire door to remain in an opening and resist the passage of flame and heat for a specified amount of time. Tests are performed by Internationally Recognized Testing Agencies such as UL Solutions, QAI, or Intertek Warnock Hersey. Horizontal fire door assemblies used to protect openings in fire-resistance-rated horizontal assemblies are tested in accordance with NFPA 288, and required to achieve a fire-resistance rating not less than the assembly being penetrated. The doors then receive an hourly rating of one to four hours, and are permanently labeled by the manufacturer so that they can be easily identified by code authorities.

See Technical Resources at the end of this article for more information on building code, OSHA and testing.

The door panel will either be insulated with fire-resistant material or may require the addition of concrete to a recessed cover pan during the installation process. In addition, most of these floor doors are equipped with a fusible link that releases the cylinders when the temperature threshold is reached, automatically closing the door to block flame and smoke. Your AHJ may require the self-closing mechanism.

NON FIRE-RATED

Non fire-rated floor doors can be used in a variety of interior or exterior applications providing ease of access to underground equipment and utility vaults. From floor doors for wet environments to heavy-duty models for vehicle traffic, a wide range of types and optional features is available.

Floor doors for exterior and wet environments usually have a channel under the door edge that drains water away from the floor opening. These may be called drainable, gutter or channel floor doors, and feature a drain coupling that can be connected to a dry well or disposal system. Review the manufacturer’s product information for details about water tightness and suitability for interior versus exterior use.

Models with unique features are available for specialty applications including water treatment plants, sidewalks, utility vault doors, basin covers, well hatches, detention, flood-tight, gas-tight or transit emergency evacuation.

INSTALLATION TYPE: Cast-in-Place versus Retrofit Drop-In

Many floor door models known as “concrete” or “cast-in-place”, are designed to be installed into a blocked-out opening in a concrete floor, and additional concrete is then filled in around the frame and anchors to secure them. It is critical to review installation instructions to plan in advance how much larger the block-out needs to be than the door frame, as they can range from a few inches up to ten inches, to allow for the anchoring hardware. Retrofit floor doors may feature a drop-in or bolt-in construction that can be attached to an existing opening in wood concrete or metal framing.

OVERVIEW OF FLOOR DOOR CONSTRUCTION

Most floor doors are designed to be flush with the surrounding floor and standard-duty floor doors are designed to withstand pedestrian traffic loads of 150 or 300 pounds per square foot. Heavy-duty models with an H20 or HS20 wheel load rating are also available for vehicle traffic.

Frame Construction: Floor door frames may be of aluminum, steel or stainless steel. When frames are intended to be in contact with concrete, a bituminous coating or other barrier coating should be applied to prevent galvanic corrosion

that may occur from concrete to metal contact.

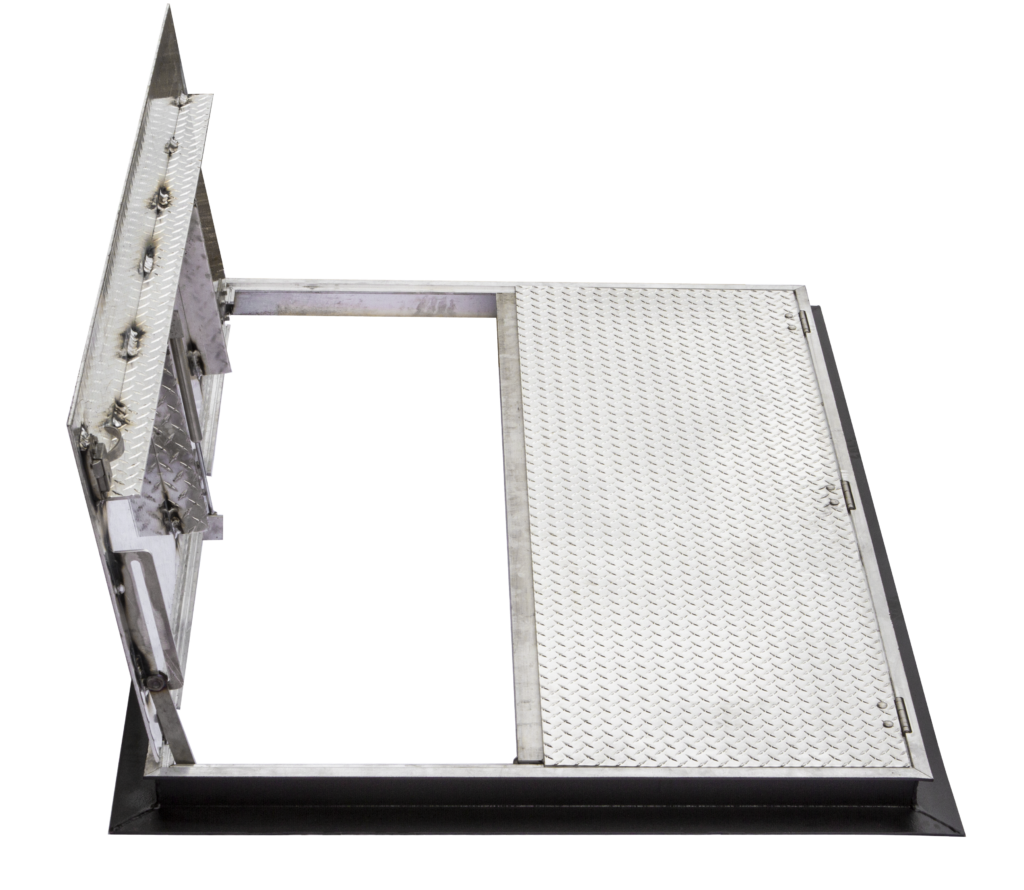

Door Panels: Depending the size and purpose, the floor door can have either a single or double door fabricated from steel, stainless steel or aluminum with reinforcements on the underside. Aluminum is more common because of weight and corrosion-resistance. Doors will either be attached by heavy-duty hinges or may be removable. A textured non-slip diamond plate is the most common type of panel, however non-textured are also offered as options for some models. When the door must match the finished surrounding floor, the panel may have a recessed door or molding strips on the surface to retain various types of flooring such as vinyl, ceramic tile, carpet or terrazzo.

Hardware: Most floor doors are equipped with stainless steel hardware to resist corrosion. Lift-assist cylinders or springs help doors open smoothly and easily, and hold-open arms on non fire-rated models keep the door safely locked in the open position during use. Many floor doors have a recessed lock or latch with a removable cover protecting the lock from dust and debris when not in use. Lock options can include padlock hasps, detention and security locks.

Optional Features: Check the manufacturer’s submittal to view options specific to their products. Options may include gasketing, weather seals, lifting handle, removable doors, motorized opening mechanisms, PVDF coating, or all-stainless construction for corrosive environments.

FALL PROTECTION FOR FLOOR DOORS

When open, floor doors are considered an opening in a walking-working surface. The Occupational Safety and Health Administration (OSHA) requires that these openings be protected against falls by one of several means. Floor doors can be protected by a range of options including a safety net or grating, a chain or a guardrail system. See the Technical Resources for more details.

TECHNICAL RESOURCES

International Building Code – 2024 (IBC)

F712.1.13 Openings: Vertical openings for floor fire doors and access doors shall be permitted where protected by Section 712.1.13.1 or 712.1.13.2.

712.1.13.1 Horizontal fire door assemblies: Horizontal fire door assemblies used to protect openings in fire-resistance rated horizontal assemblies shall be tested in accordance with NFPA 288, and shall achieve a fire-resistance rating not less than the assembly being penetrated. Horizontal fire door assemblies shall be labeled by an approved agency. The label shall be permanently affixed and shall specify the manufacturer, the test standard and the fire-resistance rating.

712.1.14 Group I-3: In Group I-3 occupancies, vertical openings shall be permitted in accordance with Section 408.5.

1015.2 Guards – Where required: Guards shall be located along open-sided walking surfaces…that are located more than 30 inches measured vertically to the floor or grade below at any point within 36 inches horizontally to the edge of the open side. Guards shall be adequate in strength and attachment in accordance with Section 1607.9.

1015.3 Height: Required guards shall be not less than 42 inches high…from the adjacent walking surfaces.

The Occupational Safety and Health Administration (OSHA)

OSHA provides standards, training, and education for safe and healthful working conditions. Following are OSHA standards that protect workers from fall hazards around floor door areas.

1910.28(b)(2) Hoist areas:

Each employee in a hoist area is protected from falling 4 feet (1.2 m) or more to a lower level by one or more of the following:

A guardrail system; personal fall protection system; or a travel restraint system. When any portion of a guardrail system, gate or chains is removed, and an employee must lean through or over the edge of the access opening to facilitate hoisting, the employee is protected from falling by a personal fall arrest system.

1910.28 (b)(3) Holes

Each employee is protected from falling through any hole (including skylights) that is 4 feet (1.2 m) or more above a lower level by one or more of the following: Covers; guardrail systems; travel restraint systems; or personal fall arrest systems.

Each employee is protected from tripping into or stepping into or through any hole that is less than 4 feet (1.2 m) above a lower level by covers or guardrail systems.

Each employee is protected from falling into a stairway floor hole by a fixed guardrail system on all exposed sides, except at the stairway entrance. However, for any stairway used less than once per day where traffic across the stairway floor hole prevents the use of a fixed guardrails system, the employer may protect employees from falling into the hole by using a hinged floor hole cover that meets the criteria of 1910.29 and a removeable guardrail system on all exposed sides, except at the entrance to the stairway.

Each employee is protected from falling into a ladderway floor hole or ladderway platform hole by a guardrail system and toeboards erected on all exposed sides, except at the entrance to the hole, where a self-closing gate or an offset must be used.

A guardrail system or a travel restraint system when a work operation necessitates passing material through a hatchway or chute floor hole.

1910.29(b)(13) Guardrail systems

When guardrail systems are used around holes that serve as points of access (such as ladderways), the guardrail system opening: has a self-closing gate that slides or swings away from the hole, and is equipped with a top rail and midrail or equivalent intermediate member that meets the requirements in paragraph (b) of this section; or is offset to prevent an employee from walking or falling into the hole. (Note: this section also defines specifications for guardrail systems, but we have not included all of those details)

Visit osha.gov for current codes

This document is a guideline only, as interpretation of building codes may vary. Consult your local AHJ for appropriate standards in your area.