Over the last year, Dur-Red has taken several steps to improve products for maximum durability and performance. Here are some of the product improvements:

- More energy-efficient R-6 polyisocyanurate on all our insulated products

- All our bolt-on components are now zinc-plated for more durability

- We have added an inside/outside manual release on the smoke vents as a standard feature

- Products made of galvanneal steel (instead of galvanized) with a factory-applied powder coat finish

More About the Benefits of Galvanneal Steel with a Powder Coat Finish:

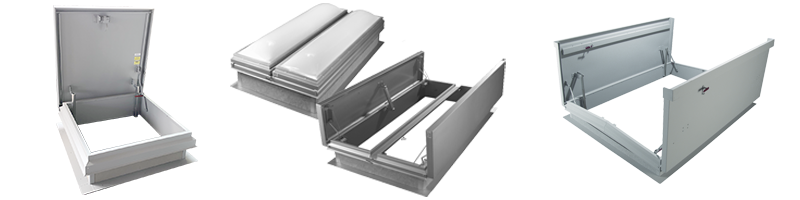

With the recent upgrades, our steel Dura Hatch™ roof and equipment hatches and Fahrenheit™ smoke vent products are now powder coat painted at the factory. We have converted all our previously galvanized products to galvanneal steel. This is now becoming the industry standard for most manufacturers, especially those who provide a powder coat factory finish. Galvanneal steel products, together with a powder coat paint, results in a synergistically improved corrosion resistance and performance.

- Dur-Red’s powder coated products are superior to competitors who only include a primer, which requires field painting to prevent rust.

Comparing Galvanneal Steel and Galvanized Steel:

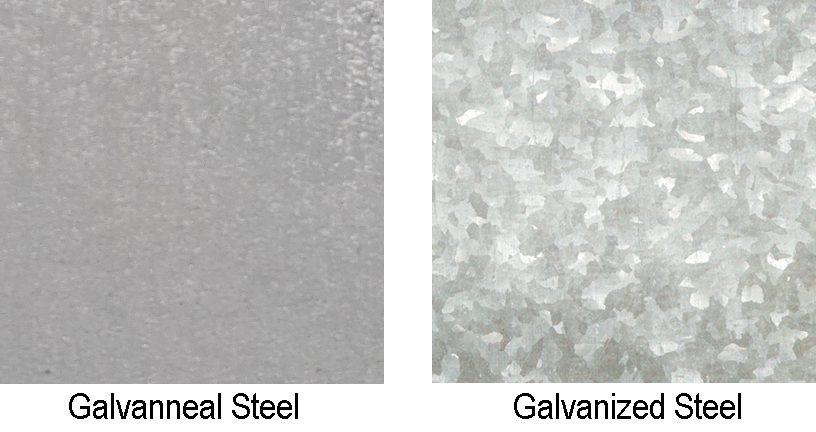

Both galvanized and galvanneal sheet steel start out similarly at the steel mills and are dipped into a hot zinc bath, so the zinc bonds to the metal’s surface. Galvanneal steel goes through an additional step where it is heated to a high temperature. This annealing process pulls the iron from the steel, causing it to bond with the zinc coating.

Benefits of galvanneal steel over galvanized steel include:

- Galvanneal steel is a much harder and more scratch-resistant steel that vastly improves formability, weldability and paint adhesion.

- Zinc-iron crystals on the surface of galvanneal steel mechanically lock to the powder paint, forming an excellent bond.

| Characteristic | Galvanneal Steel | Galvanized Steel |

| Coating | Three zinc-iron layers Harder and more durable | One zinc layer |

| Appearance | Dull gray matte appearance | Shiny metallic appearance |

| Paintability | Higher paintability, better paint adhesion with minimal pre-treatment | High paintability with profiling and priming pre-treatment of metal |

| Formability & Welding | Higher formability and more weldable | High formability |

| Corrosion Performance | Higher corrosion-resistance when combined with powder-coat paint finish | High corrosion-resistance, not always painted. |

| Cost | Higher cost, but better value | High cost |

Industry Standards for Galvanized Sheet Steel:

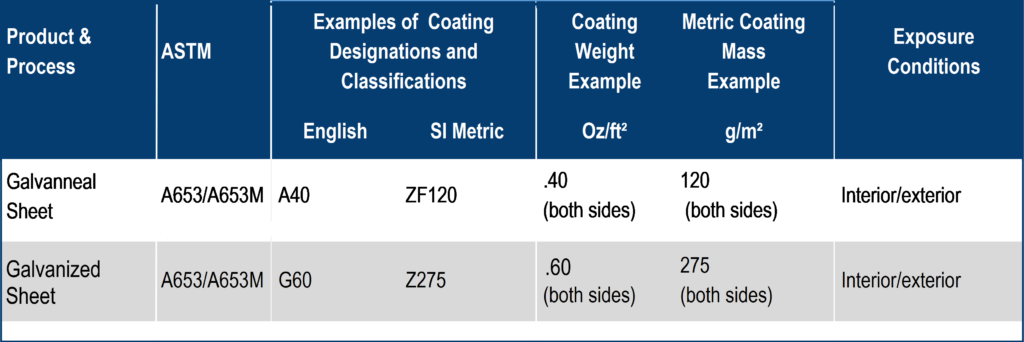

Both galvanized and galvanneal steel fall under ASTM A 653/A 653M Standard Specification for Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by the Hot-Dip Process.

In the chart below are examples of coating designations, classifications, and coating weights.

Dur-Red takes product improvement seriously. We are continuing to find ways to make our products a great value, and to offer the benefits and features that the market is looking for. Please feel free to contact us with any questions or product suggestions at sales@activarcpg.com or 800-554-6077.

For more information on Dur-Red Products or to download our new submittals and installation guides, visit https://www.activarcpg.com/products/dur-red/

This document is a guideline only, as interpretation of building codes may vary. Consult your local AHJ for appropriate standards in your area.